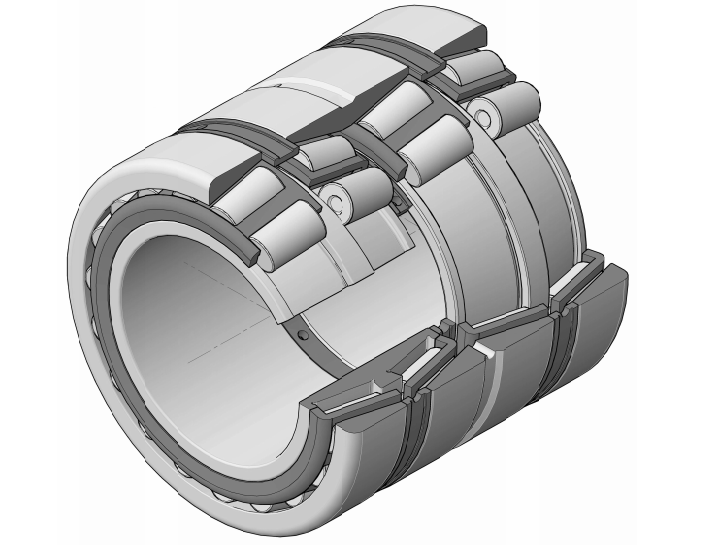

Four-row tapered roller bearings

The four-row tapered roller bearing is a specially designed angular contact bearing with a multi-row roller arrangement that can withstand both high radial and partial axial loads. The inner diameter of the bearing is designed to fit loosely with the roll neck, which is easy to install and disassemble, but the sliding creep needs to be avoided by means of a spiral oil groove. It is mainly used in four-high hot rolling mills, work rolls in cold rolling mills and billet openers, and its compactness can replace the additional thrust bearing arrangement.

Four-row tapered roller bearings offer the following key features and benefits:

Long service life

The design of four tapered outer rings (four individual outer rings) provides optimal load distribution on all four rows of rollers.

Increased operational reliability

The surface finish of the roller-raceway interface is optimized to facilitate the formation of a hydrodynamic lubricant film.

Improved abrasion resistance

The bearings are made of extremely pure and homogeneous steel and are specially heat-treated for improved wear resistance.

Improved sealing performance, reduced leakage and frictional heat generation

The seal design is optimized to ensure strong protection against external contamination while reducing friction and frictional heat generation. The seal design also allows for better lubricant preservation, minimizes environmental impact, and reduces maintenance costs.

Same load capacity for sealed and open bearings

The optimized compact seal design achieves the same internal design.

Overall bearing interchangeability

Bearings with and without spacers, as well as open and sealed bearings, have the same external dimensions. This enables the current standard design bearings to be fully interchangeable with bearings without spacer rings or with optimized seal designs.

It can be installed separately for easier inspection

Optimized spacer-less design removes and separates roller and cage assemblies and seals. This facilitates installation, disassembly, and routine maintenance checks.

If you want to know more bearing information,please contact us :

sales@cwlbearing.com

service@cwlbearing.com

Post time: Jul-07-2025