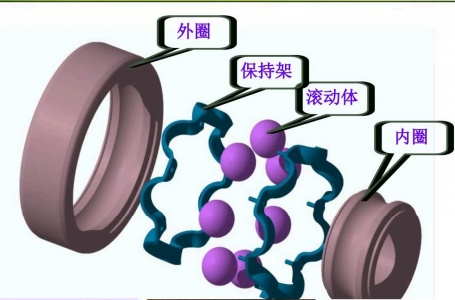

The composition of the rolling bearing and the role of each part

Rolling bearings are composed of four parts: outer ring, inner ring, rolling element and cage. Generally, the outer ring of the rolling bearing is installed in the frame bore and does not move, the inner ring is mounted on the shaft and rotates with the shaft, and the rolling element rolls between the raceways of the inner and outer rings to form rolling friction.

1 outer ring

The outer ring usually forms a transitional fit with the housing or mechanical housing bore to provide support.

2 Inner ring

The inner ring usually fits tightly with the shaft and runs with the shaft.

3 Rolling Elements

The rolling elements (steel balls, rollers or needle rollers) are usually evenly arranged between the two rings in the bearing with the help of a cage for rolling motion, and its shape, size and number directly affect the load capacity and performance of the bearing.

4 cages

In addition to evenly separating the rolling elements, the cage can also guide the rotation of the rolling elements and improve the internal lubrication performance of the bearing.

The cage can be divided into five types, namely: wave cage, crown cage, E-type cage, solid cage, chrysanthemum cage.

5 Dust cap and seal

In addition to the four main components, some bearings also need dust caps or sealing rings.

The function of the shield is to prevent external dust from entering the bearing.

Detachable dust cover – commonly known as "live cover"

Non-detachable dust cover - commonly known as "dead cover" and "fixed cover"

The function of the sealing ring is to prevent external oil, water and medium from entering the bearing.

Contact seals

Non-contact seals

More bearings information, please contact us :

sales@cwlbearing.com

service@cwlbearing.com

Post time: Jun-25-2025